Polarizing Filter

Most machine vision experts are familiar with the problem. When inspecting components, disruptive reflections often occur in the camera image. The most common causes are foils, packaging, lubricants, oils, coatings, or reflections from glossy or mirror-like surfaces.

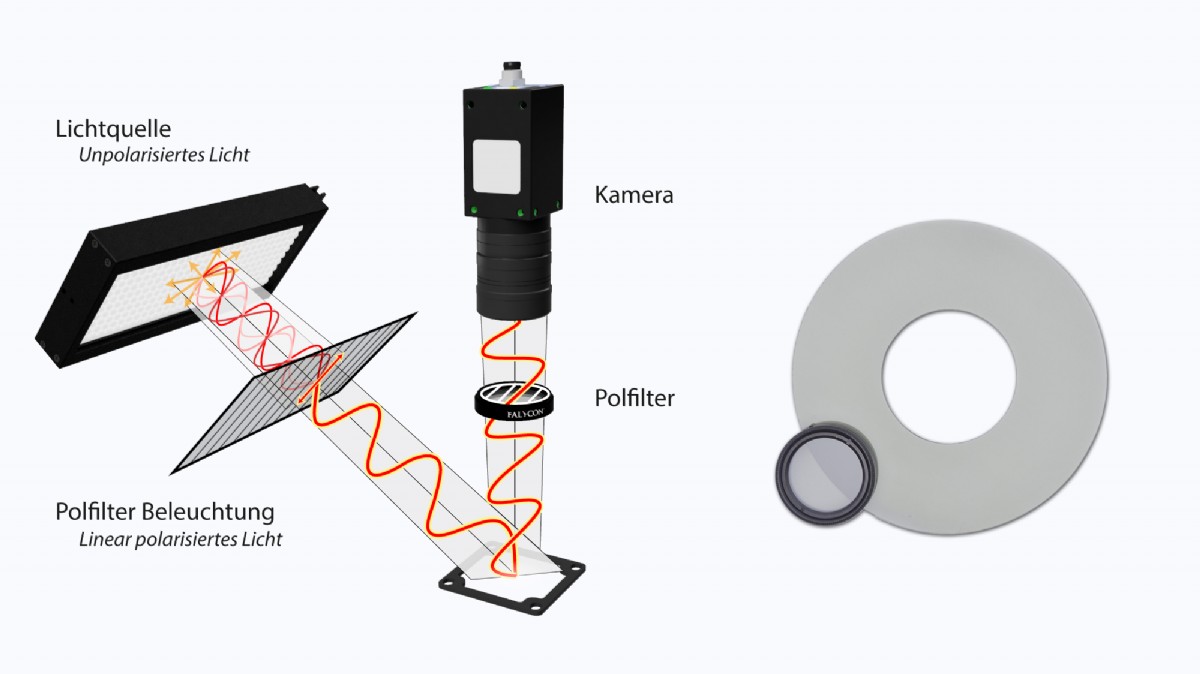

To suppress these reflections, it is recommended to place a linear polarizer in front of the camera lens and a linear polarizer in front of the illumination.

The Influence of the Polarizer

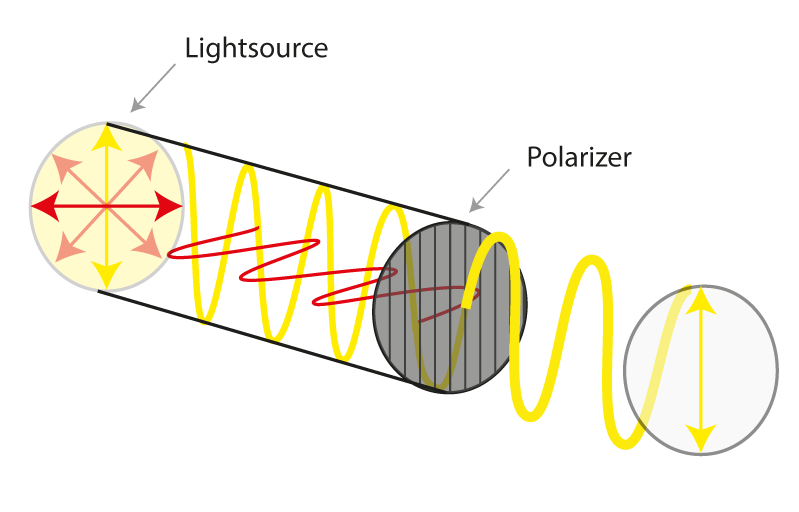

The light emitted by a light source is usually evenly distributed across all oscillation planes.

In the illustration, an electromagnetic wave (light) is visible along its propagation direction, i.e., from the illumination to the test object. Light consists of an electrical and a magnetic component, with the electrical component being associated with the polarization direction. The polarization direction thus describes an "angle" that is perpendicular to the direction of propagation. Unpolarized light encounters an object in many different polarization directions. This results in reflections at various features or surfaces.

Polarizer in Incident Light

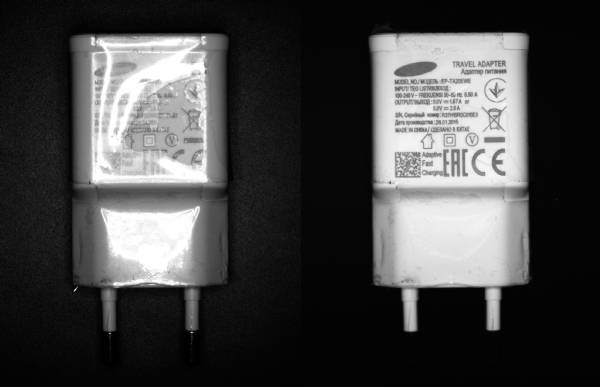

What you see is the large-scale reflection of the foil packaging of the charger.

When using polarized light and another polarizer directly in front of the lens, unwanted reflections can be filtered out. The polarizer in front of the illumination ensures emitted light with only one polarization direction and thus reduces reflections on the test piece. The second filter in front of the lens ensures that even the remaining reflections can still be filtered out. In addition to inspecting foil-wrapped articles, reflective metals, or plastic products, other testing tasks are conceivable. In chemistry, for example, different types of sugars (sucrose, fructose) and their concentration can be determined using polarizers.

To suppress these reflections, it is recommended to place a linear polarizer in front of the camera lens and a linear polarizing disc in front of the illumination.

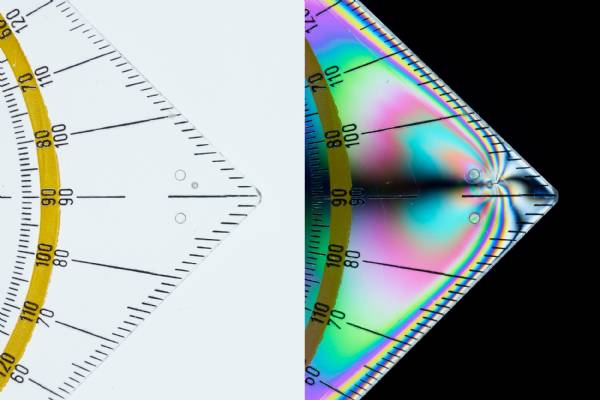

Polarizer in Transmitted Light

In addition to this, polarized light can be used to determine material stresses or surface scratches in transmitted light. Plastic objects have different material stresses due to their manufacturing, which become visible through the application of a polarizer.